When using an ultrasonic cleaner, the choice of basket plays a crucial role in determining the cleaning effect and efficiency. The materials, structures, and designs of cleaning baskets can have an impact on the spread of ultrasonic waves, the protection of items being cleaned, and the overall convenience of the cleaning process.

The basket is able to effectively protect the items that require cleaning and prevent damage caused by collision, friction, and other factors during the cleaning process. This is especially crucial for precision instruments and wearing parts, making a suitable basket design particularly important. The use of a cleaning basket ensures that items are evenly distributed in the cleaning tank, thereby avoiding the issue of uneven cleaning due to stacking. This helps to evenly distribute ultrasonic energy and improve the overall cleaning effect. Additionally, using a cleaning basket makes it easier to load and unload items, reduces direct contact with the cleaning solution, and enhances both safety and operational efficiency.

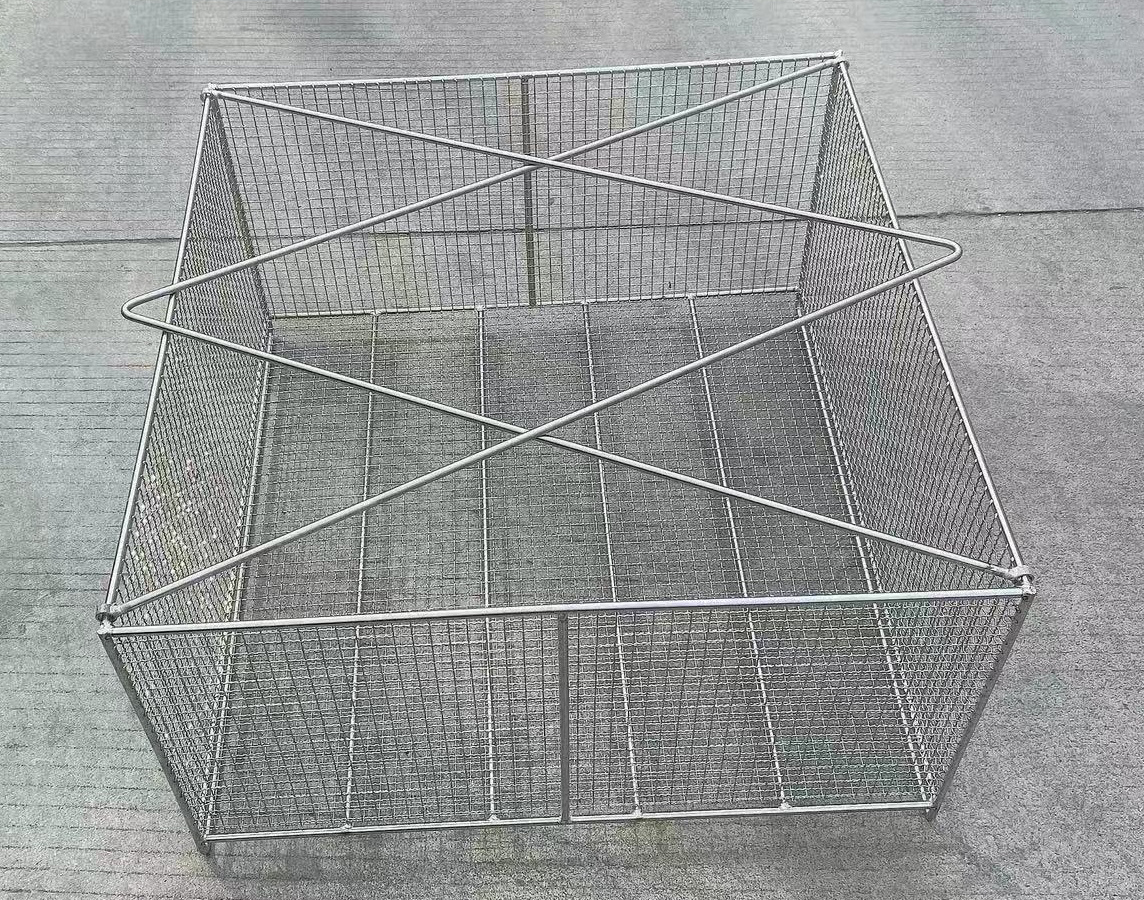

Stainless steel basket

Stainless steel baskets are commonly used for cleaning baskets, which have the characteristics of corrosion resistance, high temperature resistance, robustness and durability. Suitable for most industrial and laboratory cleaning applications.

Plastic basket

The plastic basket is lightweight and easy to operate, but it has poor resistance to high temperatures and chemical corrosion. Plastic baskets are primarily used for cleaning small and delicate workpieces, such as electronic components and plastic products. Due to their light weight, they are easily handled and operated frequently.

Galvanized basket

Galvanized baskets possess certain anti-rust properties and are more cost-effective, but they do not offer the same level of corrosion resistance and durability as stainless steel baskets. Galvanized baskets are suitable for cleaning general mechanical parts, tools, etc., making them a good choice for cost-sensitive applications with high cleaning requirements.

Cleaning baskets play an important role in the use of ultrasonic cleaning machines. Selecting the appropriate material and structure for the cleaning basket can enhance the cleaning effectiveness, safeguard the workpiece, and improve operational efficiency. Egsonic specializes in customizing baskets of various sizes and structures, boasting extensive experience in customization. For professional cleaning solutions, please feel free to contact us.

For more information, please contact the EGSONIC team at info@egsonic.com